Power Pack: A Complete Engine System That Just Works

By Bradley Krahn

Design Engineering Team Lead at DEUTZ Corporation

Summary:

For many OEMs, engine integration has quietly become one of the most costly and frustrating parts of launching a new machine. Teams spend months chasing compatibility issues, thermal problems, and compliance concerns that should have been solved before the project even started. Every delay affects your bottom line. Every failure in the field puts your brand at risk.

This article outlines how DEUTZ Power Packs help OEMs eliminate those risks by delivering a complete, ready-to-run power system. Not just an engine, but an engineered solution built around your machine. We’ll walk through what’s included, why it matters, and how this approach helps teams move faster with more confidence.

Why OEMs are Shifting Away from DIY Integration

On paper, buying a standalone engine and integrating it into your machine seems simple. But most engineering leaders already know how messy that path can get. A typical engine integration project runs into:

-

Cooling systems that aren’t matched to real-world duty cycles

-

Mounting issues that affect vibration, service access, or structural integrity

-

Electrical compatibility challenges with control panels and diagnostics

-

Airflow problems that cause early failures or emissions faults

-

Constant back-and-forth with vendors who don’t own the full picture

-

Warranty risk falling back on your team due to incomplete compliance

All of that adds up to wasted time, unpredictable launches, and ongoing service problems. And with emissions regulations constantly evolving, the risks are only increasing.

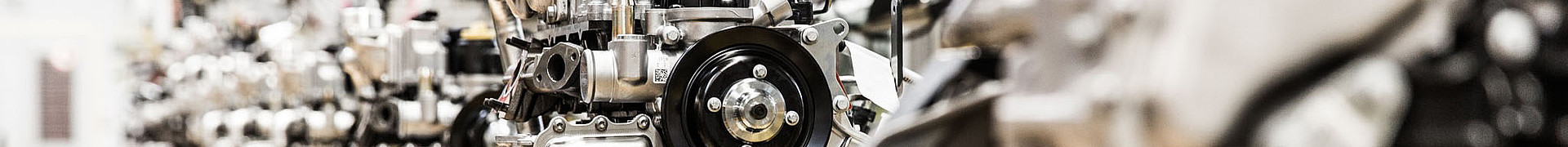

What a DEUTZ Power Pack Actually Delivers

A Power Pack from DEUTZ is not just an engine. It is a pre-engineered system built to drop into your machine with minimal modification. Each pack includes:

-

A complete, emissions-certified DEUTZ engine

-

Fully integrated cooling, filtration, and airflow systems

-

Mounts, brackets, and installation hardware

-

Calibration and documentation specific to your use case

-

DEUTZ application engineering and warranty support

The goal is not just to sell you an engine. The goal is to deliver a system that works on day one, without requiring your team to solve every detail from scratch.

More Than Convenience. This is About Control.

OEMs who switch to Power Packs are not just looking for speed. They are looking to take control of project timelines, warranty exposure, and field performance.

When your team builds the integration in-house, you are responsible for:

-

Ensuring thermal modeling was done correctly

-

Verifying emissions routing complies with documentation

-

Troubleshooting mounting vibrations or component fatigue

-

Answering service teams when components are hard to access

-

Holding the line when customers face failures and expect a solution

When DEUTZ provides the complete system, those risks shift. We take responsibility for the integration. That means our warranty covers not just the engine, but the entire package as delivered.

Why This Matters for Engineering Teams

Design and project engineering teams are under more pressure than ever. Lead times are tight. Resources are limited. And most organizations are trying to do more with fewer people.

When you buy a DEUTZ Power Pack, you are not just saving time. You are clearing space in your team’s bandwidth to focus on the parts of your machine that actually differentiate your product.

Instead of spending 3 to 6 months figuring out engine fitment, airflow, and thermal issues, you are starting with a known system that is already validated. You are not building backwards from service problems that show up in the field. You are starting from a design that has already been tested for those edge cases.

From Engineering Concept to Field Deployment

The process looks like this:

-

Select a baseline configuration based on your machine class or application

-

Review any needed adjustments for footprint, controls, or customer preferences

-

Receive a fully assembled, drop-in package ready to install

-

Install the Power Pack using provided instructions and documentation

-

Deploy the machine with confidence, knowing it is backed by DEUTZ engineering and warranty coverage

This is not a consultation and some rough CAD models. This is a physical product with a repeatable BOM, scalable to your production needs, and supported long term.

Results That Show Up on the Bottom Line

Customers who use DEUTZ Power Packs typically report:

-

Faster development cycles

-

Fewer late-stage engineering changes

-

Reduced in-field warranty claims

-

Easier service access and standardization

-

Lower emissions compliance risk

-

Higher confidence from both internal teams and end customers

And perhaps most importantly: a machine that performs better because the power system was designed as part of the solution, not as an afterthought.

Moving Forward

If your team is currently integrating engines in-house—or managing field problems from past builds—a Power Pack program may be the next step forward.

Reach out to see what it looks like for your machine, your team, and your schedule. We will walk you through available packages, requirements, and common integration paths.

A better system already exists. You do not need to build it from scratch. Let’s move your next project forward—faster, simpler, and with a lot fewer surprises.